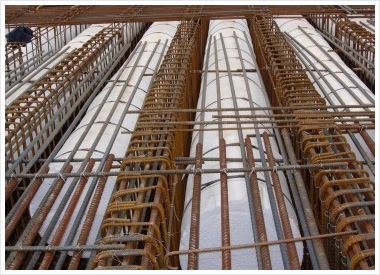

Void formers tubes obtain very high radial rigidity by means of special corrugations and are thus highly suitable as void formers these tubes are embedded, thus reduce the dead weight of the structure.

Area of use

In building projects such as bridges and quaysides, void tubes make possible large spans thanks to reduction in dead weight and thus permit good technical, aesthetic and economic solutions.

- Void forming tubes meet the requirements of concrete structures for highly rigid but light sheet metal tube that can withstand being embedded without deformation.

- The seam is entirely tight, thus preventing water from entering the tube.

- The low weight makes tube handling easy and their internal seams and corrugations ensure that the tubes did not catch on each other, facilitate the mounting of female ended cones or caps.

- Void formers are sealed with end cones that are supplied, fitted to the tubes.

- Void formers are withstanding reinforcement loads & transportation as well fast tempo casting.